Keeping your tanks in top shape is crucial for safety and efficiency. But do you know which tools make weekly maintenance easier and more effective?

If you want to save time, prevent costly repairs, and ensure your tanks last longer, this guide is for you. You’ll discover essential tools that simplify every step of your maintenance routine. Ready to take control of your tank upkeep and avoid unexpected problems?

Keep reading to find out exactly what you need.

Credit: naavagreen.com

Key Maintenance Tasks

Maintaining tanks weekly is important for safety and efficiency. Regular checks help catch problems early.

Using the right tools makes maintenance easier and more effective. Focus on inspection, cleaning, and leak detection.

Inspection Procedures

Inspect tanks to find signs of wear or damage. Check all parts carefully for cracks or rust.

Use flashlights and mirrors to see hard-to-reach areas. Record any issues found for repair.

- Visual check of tank surface and joints

- Check seals and gaskets for tightness

- Inspect valves and fittings for damage

- Look for corrosion or rust spots

Cleaning Requirements

Clean tanks regularly to prevent buildup of dirt and sludge. This keeps the tank working well.

Use brushes, scrapers, and water jets to remove deposits. Follow safety rules during cleaning.

- Remove loose debris with a brush

- Scrape off stubborn deposits

- Rinse with clean water or pressure washer

- Dry the tank before use

Leak Detection

Find leaks early to avoid big problems. Use tools that detect moisture or pressure changes.

Check joints, seals, and welds closely. Use leak detection spray or electronic sensors if available.

- Look for wet spots or stains

- Use leak detection spray on suspect areas

- Listen for hissing sounds

- Monitor pressure gauges for drops

Essential Tools

Weekly maintenance of tanks keeps them safe and working well. Using the right tools helps spot problems early.

This guide covers essential tools used for tank inspection and repair during weekly checks.

Inspection Cameras

Inspection cameras let you see inside tanks without opening them. They help find cracks or dirt.

These cameras often have lights and long cables to reach deep areas. They provide clear video or photos.

Cleaning Equipment

Cleaning equipment removes dirt, sludge, and buildup inside tanks. Clean tanks work better and last longer.

Tools include brushes, scrapers, and pressure washers. Each tool suits different tank sizes and materials.

- Handheld brushes for small spots

- Long-handled scrapers for hard-to-reach areas

- Pressure washers for heavy dirt removal

Sealants And Repair Kits

Sealants stop leaks and protect tanks from damage. Repair kits fix cracks and holes quickly.

These kits usually include putty, adhesives, and patches. They work on metal, plastic, and concrete tanks.

Safety Gear

Weekly maintenance of tanks requires the right safety gear. Proper gear protects workers from injuries and hazards.

Using safety equipment reduces risks during cleaning and inspection tasks. Always wear the correct gear.

Protective Clothing

Protective clothing shields the body from chemicals and sharp objects. It helps prevent skin contact with harmful substances.

Wear clothes made from durable, chemical-resistant materials. Cover arms and legs fully to avoid exposure.

- Chemical-resistant coveralls

- Gloves made of nitrile or rubber

- Waterproof boots with slip resistance

- Hard hats to protect the head

Respiratory Protection

Respiratory gear protects lungs from harmful fumes and dust inside tanks. Breathing clean air is critical for safety.

Use masks or respirators suited for the chemicals in the tank. Check that filters are clean and working well.

- Disposable dust masks for light dust

- Half-face respirators with cartridges

- Full-face respirators for toxic gases

- Air-supplied respirators for confined spaces

Fall Protection

Fall protection prevents injuries from slips or falls during tank work. Tanks can have slippery or uneven surfaces.

Wear harnesses and use lifelines when working at heights. Secure all gear and check anchor points before starting work.

- Full-body safety harness

- Shock-absorbing lanyards

- Anchorage connectors

- Guardrails and safety nets

Credit: www.ebay.ca

Automation Aids

Automation aids improve the weekly maintenance of tanks. They help reduce manual checks and increase safety.

Using technology, workers can track tank conditions more easily. This lowers risks and saves time.

Sensor Technology

Sensors measure tank levels, temperature, and pressure automatically. They send real-time data to operators.

- Level sensors detect liquid amounts inside tanks

- Temperature sensors monitor heat changes

- Pressure sensors alert about unsafe conditions

- Leak detectors identify spills early

- pH sensors check water quality

Remote Monitoring Devices

Remote devices allow tank data to be checked from any location. They support quick decisions and alerts.

| Device | Function | Benefit |

| Wireless Transmitters | Send sensor data remotely | Reduces on-site visits |

| Mobile Apps | Display tank status on phones | Easy access anytime |

| Alarm Systems | Alert for abnormal readings | Faster response to problems |

Tool Maintenance Tips

Maintaining tools for weekly tank care keeps them working well. Proper care extends tool life and ensures safety.

Simple maintenance steps help avoid costly repairs and keep tanks clean and efficient.

Cleaning And Storage

Clean tools after each use to stop rust and damage. Dry tools completely before storing them.

- Use mild soap and water for cleaning

- Dry tools with a soft cloth

- Store tools in a dry, cool place

- Keep tools organized to avoid damage

Regular Calibration

Check tool accuracy often. Calibrate tools to keep measurements correct and reliable.

| Tool Type | Calibration Frequency | Calibration Method |

|---|---|---|

| Pressure Gauges | Monthly | Use a standard pressure source |

| Flow Meters | Quarterly | Compare with a known flow rate |

| Thermometers | Biannually | Check with a calibrated reference |

Replacement Schedules

Replace worn or damaged tools on time. Follow a schedule to avoid failures during tank maintenance.

- Inspect tools weekly for wear or damage

- Replace parts like seals and gaskets every 3 months

- Change hoses and connectors every 6 months

- Discard tools that no longer work safely

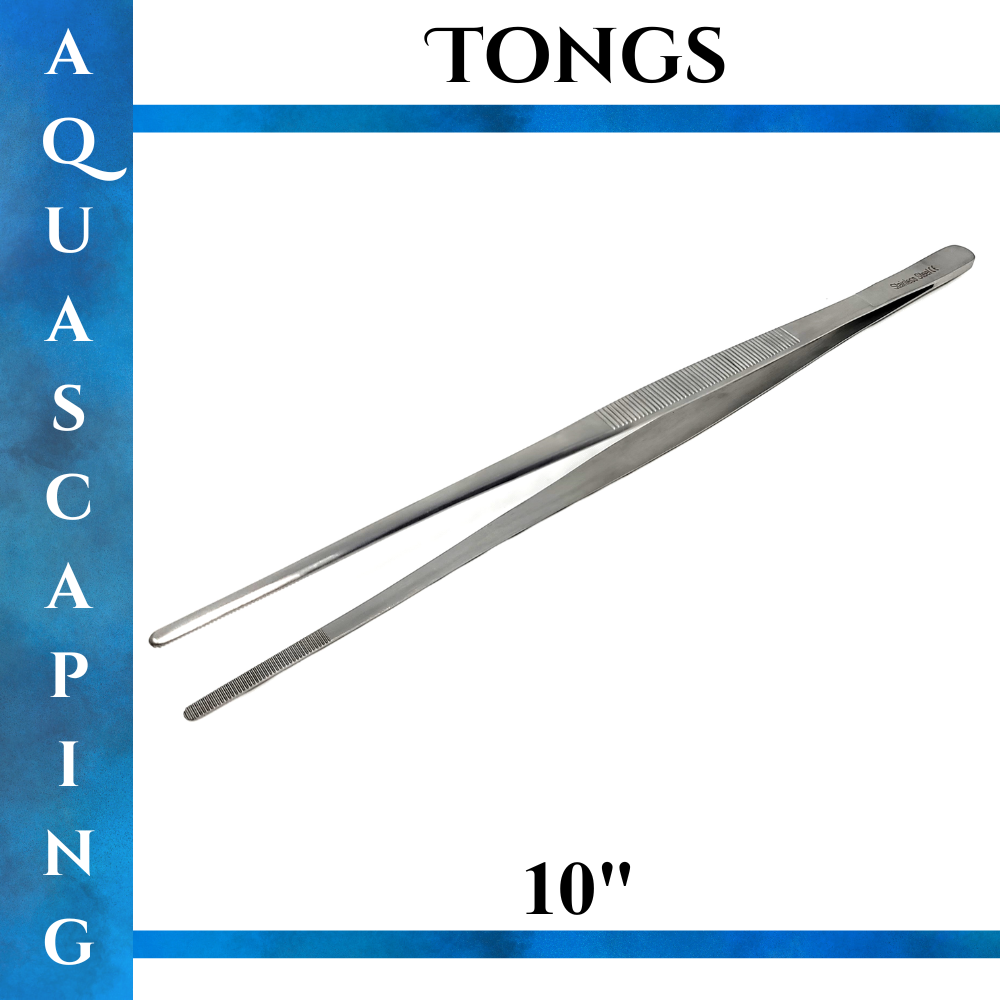

Credit: www.amazon.com

Choosing The Right Equipment

Maintaining tanks weekly needs the right tools. Choosing equipment wisely saves time and effort.

Here, we explore how to select tools based on tank types, budget, and vendors.

Assessing Tank Types

Different tanks need different tools. Understand the tank type before buying equipment.

- Freshwater tanks may need specific filters.

- Saltwater tanks require stronger cleaning tools.

- Planted tanks benefit from gentle maintenance tools.

Budget Considerations

Plan your budget to avoid overspending. Set a clear limit for equipment costs.

Consider the long-term value of quality tools. Cheaper tools might need frequent replacement.

Vendor Selection

Choosing the right vendor ensures quality and support. Research different vendors before buying.

- Read reviews from other tank owners.

- Check if vendors offer warranties.

- Compare prices and customer service.

Frequently Asked Questions

What Are Essential Tools For Weekly Tank Maintenance?

Essential tools include inspection mirrors, cleaning brushes, water test kits, and protective gear. These help monitor tank condition and prevent contamination. Regular tool use ensures tank safety and longevity.

How Often Should Tanks Be Inspected During Maintenance?

Tanks should be inspected weekly to detect leaks, corrosion, and sediment buildup. Frequent checks help prevent costly repairs and maintain water quality. Early detection ensures efficient tank operation.

Why Use Water Test Kits In Tank Maintenance?

Water test kits measure pH, chlorine, and contaminants in tanks. They ensure water safety and compliance with health standards. Regular testing helps maintain clean and safe tank water.

What Safety Gear Is Needed For Tank Maintenance?

Safety gear includes gloves, goggles, respirators, and protective clothing. These protect workers from harmful chemicals and contaminants. Proper gear ensures safe and effective maintenance procedures.

Conclusion

Regular tank maintenance keeps your system running smoothly. Using the right tools makes tasks easier and faster. Small problems get fixed before they grow bigger. Clean tanks prevent damage and save money. Weekly checks help avoid costly repairs later. Choose tools that match your tank’s size and type.

Stay consistent and protect your investment. Simple habits lead to long-lasting, efficient tanks. Keep tools ready and follow a maintenance plan. Your tanks will stay safe and work well.