Are you looking to get the most out of your medium tank? The right feeding tools can make all the difference in how smoothly your tank operates and how well it performs in the field.

Whether you’re a hobbyist or a professional, understanding these tools will save you time, improve efficiency, and keep your tank running at its best. Keep reading to discover which feeding tools you need and how they can transform your tank experience.

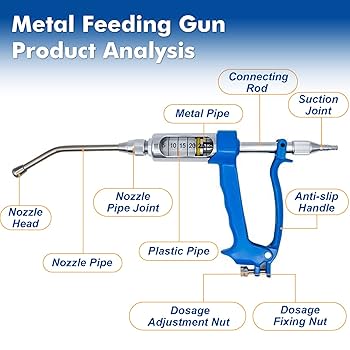

Credit: www.amazon.com

Key Features Of Feeding Tools

Feeding tools for medium tanks help handle food and fuel safely. They must meet strict standards to work well.

This guide covers the main features of these feeding tools. We focus on durability, design, and tank compatibility.

Durability And Materials

Feeding tools must last in tough conditions. They use strong materials to resist wear and damage.

- Made with high-grade steel or aluminum

- Corrosion-resistant coatings for long life

- Sealed joints to prevent leaks and cracks

- Designed to handle heavy loads and impact

Ergonomic Design

Easy handling is key for feeding tools. Designs reduce worker fatigue and improve safety.

| Feature | Benefit |

|---|---|

| Comfort grips | Reduce hand strain during use |

| Lightweight structure | Allows long use without tiredness |

| Balanced shape | Improves control and accuracy |

| Non-slip surfaces | Enhance safety in wet conditions |

Compatibility With Medium Tanks

These feeding tools fit most medium-sized tanks. They must match tank openings and systems.

- Standard sizes for tank openings

- Adapters available for different models

- Easy to attach and detach

- Designed to prevent spills and leaks

Credit: www.dugoutnorthbrook.com

Types Of Feeding Tools

Feeding tools help supply fuel or ammunition to medium tanks efficiently. Different types suit various operational needs and tank models.

Understanding these feeding tools helps in choosing the right system for specific tank requirements and battlefield conditions.

Manual Feeders

Manual feeders require soldiers to load ammunition or fuel by hand. They are simple and do not need power sources.

- Low cost and easy to repair

- Depend on crew skill and speed

- Can be slower during intense situations

- Suitable for tanks with limited automation

Automatic Feeders

Automatic feeders use mechanical or electronic systems to supply ammunition or fuel. They reduce crew workload and increase feeding speed.

| Feature | Description |

|---|---|

| Speed | Fast and consistent feeding |

| Reliability | Depends on maintenance and electronics |

| Complexity | More complex than manual systems |

| Power | Requires electrical or hydraulic power |

Hybrid Systems

Hybrid systems combine manual and automatic feeding methods. They offer flexibility depending on the situation and system condition.

Advantages of hybrid systems include:

- Backup manual feeding if automation fails

- Optimized feeding speed with crew control

- Balance between simplicity and technology

Choosing The Right Feeding Tool

Feeding tools help deliver food to medium tanks efficiently. Picking the right tool keeps tanks healthy and saves time.

Different tanks need different feeding tools. You must find the tool that fits your tank’s needs well.

Assessing Tank Requirements

Look at the size and type of your medium tank. Some tools work better with certain tank shapes and sizes.

Check how much food your tank needs each day. Feeding tools should match this amount to avoid waste.

- Tank volume and dimensions

- Type of animals in the tank

- Daily food amount

- Water flow and filter type

Evaluating Tool Performance

Test how well the tool delivers food without clogging or spilling. Good tools save food and reduce mess.

Look for tools that are easy to clean and maintain. This keeps the feeding system working smoothly over time.

- Reliable food delivery

- Simple cleaning process

- Durable materials

- Minimal maintenance needs

Cost Vs. Efficiency

Compare the price of feeding tools with how well they work. Sometimes spending more saves money later.

Think about the tool’s energy use and food waste. Efficient tools lower long-term costs and help the environment.

| Cost Factor | Efficiency Factor |

|---|---|

| Initial purchase price | Food delivery accuracy |

| Energy consumption | Maintenance frequency |

| Replacement parts cost | Durability and lifespan |

| Cleaning time | Ease of use |

Maintenance Tips For Feeding Tools

Feeding tools for medium tanks need regular care to work well. Proper maintenance keeps them reliable and safe to use.

Follow simple steps to clean, inspect, and fix common problems. This will extend the life of your feeding tools.

Cleaning Practices

Clean feeding tools after every use. Dirt and grime can cause damage and blockages.

- Use a soft cloth to wipe surfaces

- Remove any stuck debris carefully

- Apply light oil to moving parts

- Do not use harsh chemicals that harm metal

- Let tools dry completely before storing

Regular Inspections

Check feeding tools often to find wear or damage early. Look for cracks, loose parts, or rust.

| Inspection Point | What to Check | Action Needed |

| Surface | Cracks or rust spots | Clean or replace |

| Joints | Looseness or stiffness | Tighten or lubricate |

| Moving Parts | Free movement | Oil or repair |

| Handles | Secure grip | Fix or replace |

Troubleshooting Common Issues

Feeding tools may face issues like jamming or poor feeding. Fix these quickly to avoid delays.

- If the tool jams, clean and remove any blockage

- Lubricate parts that do not move smoothly

- Replace worn or broken components immediately

- Test the tool before use to ensure proper function

Innovations In Feeding Technology

Feeding tools for medium tanks have seen many improvements. These changes help tanks work better and faster on the field.

New feeding technologies focus on smart systems, automation, and future trends. Each area brings new ways to improve tank operations.

Smart Feeding Systems

Smart feeding systems use sensors and controls to manage food supplies. They reduce waste and keep the tank crew well-fed.

- Monitor food levels automatically

- Adjust portions based on crew needs

- Detect spoilage and alert the crew

- Integrate with other tank systems

Automation And Ai Integration

Automation in feeding tools cuts manual work. AI helps predict the best feeding times and supplies needed.

| Feature | Benefit |

| Automated portion control | Reduces food waste |

| AI-based supply forecasting | Prevents shortages |

| Real-time system alerts | Improves crew safety |

| Remote system control | Enhances convenience |

Future Trends

The future will bring more compact and energy-saving feeding tools. New materials will make them lighter and more durable.

Upcoming features may include:

- Self-cleaning feeding units

- Solar-powered energy systems

- Integration with wearable crew health monitors

- Use of biodegradable packaging

Case Studies And Real-world Applications

Feeding tools for medium tanks are crucial in real-world scenarios. These tools help ensure efficient operations in various environments.

Let’s explore how these tools perform in military deployments, training environments, and through performance reviews.

Military Deployments

In military deployments, feeding tools play a vital role. They ensure tanks are ready for action at all times.

Training Environments

Training environments test the limits of feeding tools. These tools must adapt to various scenarios and conditions.

- Simulated battle conditions

- Various weather scenarios

- Different terrain challenges

Performance Reviews

Performance reviews help assess the effectiveness of feeding tools. They provide data for improvements.

| Review Aspect | Outcome |

| Reliability | High |

| Efficiency | Improved |

| Adaptability | Moderate |

Credit: www.amazon.com

Frequently Asked Questions

What Are Essential Feeding Tools For Medium Tanks?

Essential feeding tools include fuel funnels, grease guns, and oil cans. These tools help maintain efficient fuel and lubricant flow, ensuring smooth tank operation and longevity during missions or training.

How Do Feeding Tools Improve Medium Tank Performance?

Feeding tools ensure proper fuel and lubricant delivery to tank components. This reduces wear and tear, prevents breakdowns, and enhances overall engine efficiency and reliability in medium tanks.

Which Feeding Tools Prevent Medium Tank Engine Damage?

Fuel filters, grease guns, and oil pumps prevent engine damage. They keep contaminants out and ensure consistent lubrication, protecting the engine from overheating and mechanical failure.

How Often Should Feeding Tools Be Used On Medium Tanks?

Feeding tools should be used before every mission and during regular maintenance. This routine keeps fuel and lubrication systems clean, ensuring optimal tank performance and reducing repair costs.

Conclusion

Choosing the right feeding tools helps improve your medium tank’s performance. Simple tools save time and effort during feeding. They keep your tank clean and running smoothly. Using proper tools reduces wear and damage to parts. Regular care with good tools makes your tank last longer.

Small steps lead to big improvements in tank maintenance. Stay consistent and pay attention to details. Good feeding tools make tank care easier every day.